If you have a pressure washer, then you need a pressure washer pump. Pressure washer pumps are the source of the power that pressure washers use to clean surfaces. The pump is responsible for converting energy from the engine of the pressure washer into the high-pressure output that will do all of the cleaning.

Pressure Washer Pumps have an important job. They are responsible for pressurizing the water that comes from your garden hose to such a high degree that it can blast away all sorts of surface materials including grime, dirt, and even paint. The pressurized water stream is also effective at cleaning concrete, metal, glass, and plastic surfaces. All pressure washer pumps work in a similar manner.

Types of Pressure Washer Pumps

Pressure Washer Pump is one of the most important component in any pressure washer. If your pressure washer pump is not working properly, it will greatly affect the performance of your pressure washer. Pumps are the part of the pressure washer that actually generates the water pressure.

There are three main types of Pressure Washer pumps: Wobble Pumps, Triplex Pumps, and Axial Cam Pumps.

There are three main types of pressure washer pumps and this is the brief details on three types of pressure washer pumps. Wobble pumps are the most popular because they’re easy to use and don’t require any special skills or training. Triplex pumps are similar to wobble pumps but they’re more durable and last longer than other brands. Axial cam pumps are the highest quality but also the most expensive option out there. They offer the best performance but are generally only used by professionals who know what they’re doing. Each type has its own set of pros and cons that make them more or less suitable for certain applications.

Wobble Pumps

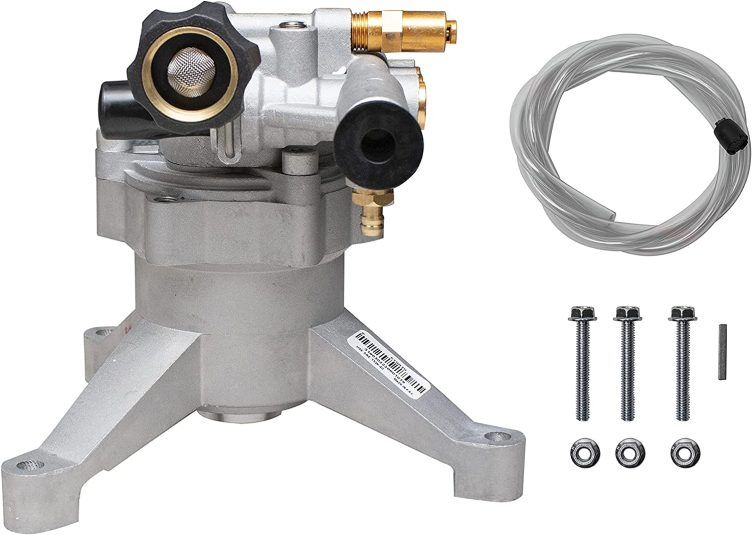

Wobble pumps are a type of direct drive pressure washer pump that uses a crankshaft to create pressure. The crankshaft is connected to a series of pistons that move up and down in chambers filled with water. As the pistons move up and down, they create a vacuum that sucks water into the chamber. when the piston reaches the top of the chamber, the water is forced out through a nozzle at high pressure.

These pumps are less expensive than belt drive pumps, but they are also less durable and require more maintenance. Wobble pumps are connected directly to the engine, and they have a tendency to wobble when the engine is running. This can cause the pump to wear out prematurely. However, they do tend to be noisier than other options so keep that in mind if noise will be an issue for you (i.e., if you’ll be using it at night when people are trying to sleep).

Advantages of Wobble Pumps

Wobble pressure washer pumps are one of the most efficient ways to clean your home or business. Here are just a few reasons why they’re worth investing in:

- They’re powerful. A good wobble pressure washer pump will be able to handle any job you throw at it, no matter how dirty or tough the surface is. And since they’re so strong, they won’t wear out as quickly as other models would.

- They have fewer parts than other brands do. We all know how annoying it is when something breaks mid use. luckily, this doesn’t happen often with wobble pressure washer pumps because they’re made with durable materials and engineered for longevity.

- They offer great value for your money. These products are priced competitively compared to similar items on the market today, So if you want premium quality without breaking the bank, then this is the best option for you.

- They don’t have any moving parts, so they’re extremely durable and can handle tough conditions.

- They’re lightweight and portable, so you can take them with you anywhere you need some cleaning done quickly and easily.

Triplex Pumps

Triplex pumps are a type of positive displacement pump that moves fluid using three pistons. Each piston is driven by a motor, and the pistons move in a circle around a central hub. This pump is used in industrial settings to move large amounts of fluid. Triplex pumps are a great option for both fresh and salt water aquaria. These pumps are capable of moving a large quantity of water quickly and efficiently, making them perfect for keeping tanks and aquariums stocked with fish and other aquatic life.

Triplex pumps are a type of centrifugal pump that uses three impellers to increase the pumping speed. These pumps are used in a wide variety of applications, including water treatment, oil and gas extraction, and food processing. Triplex pumps are a valuable tool for increasing efficiency and reducing waste. They are ideal for applications where high-volume, low-pressure liquid transfer is necessary, such as chemical and food processing plants.

These offer high pressure at low RPMs which means they’re great for energy efficiency as well as lower noise levels than other options out there on the market today but they do tend to be more expensive than other options available on the market today so keep that in mind before making your decision. These are a step up from wobble pumps because they’re quieter and more efficient than their predecessor. However, they tend to be more expensive than wobble pumps as well.

Working of Triplex Pumps

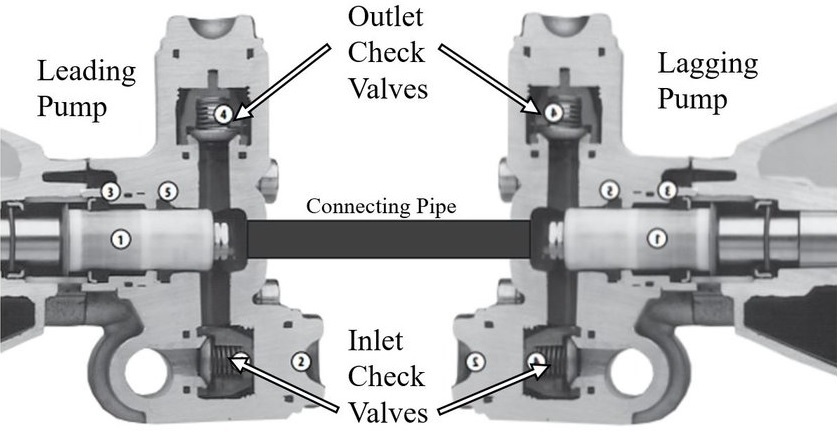

Triplex pumps are a type of pump that use three pistons to move the fluid. As the pistons move, they create a displacement of fluid that pushes the fluid against the pump’s impeller. This type of pump is used in industrial and agricultural settings, as well as in water treatment plants. Triplex pumps has three chambers that are in series.

The first chamber is at the inlet of the pump, the second chamber is at the outlet, and the third chamber is in between the inlet and the outlet. The pressure in each chamber is equal, so the pressure at the outlet is three times the pressure in the first chamber and twice the pressure in the second chamber. This allows the pump to move more fluid than a single chamber pump.

Triplex pumps can be operated in three directions: forward, reverse, and peristaltic. Each direction has its own advantages and disadvantages. Triplex pumps are most commonly used in medical applications, such as to circulate blood. Forward pumping action circulates the blood in a circle around the pump, while reverse pumping action pushes the blood forward and peristaltic action pulls the blood through the pump.

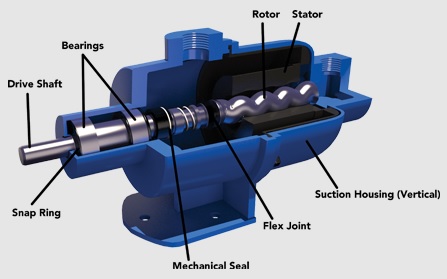

Triplex pumps use three rotors to create a single suction or discharge. This type of pump is popular because it is able to handle a high flow rate and is compact, making it easy to install. Triplex pumps are designed to move liquids and slurries in three dimensions. These pumps are often used in the petroleum, chemical, and food industries.

Advantages of Triplex Pumps

The Triplex line of pressure washer pumps offers many benefits over other brands on the market today. Here are just a few:

- These pumps are durable built to last. They can handle regular use without breaking down like some other products out there today.

- The Triplex line offers great performance at an affordable price point compared to other brands on the market today.

- This brand has a proven track record when it comes to reliability, which is something that other brands can’t claim easily.

- There are different sizes available in this line so you’re sure to find one that fits your needs perfectly whether you need something small for your personal vehicle or something larger for use on a commercial job site or even something in between those two extremes.

- This brand offers great warranties on their products so you know that if anything does go wrong with them during normal use then they’ll be able to replace or repair it for you quickly and easily without any hassle on your end.

Axial Cam Pumps

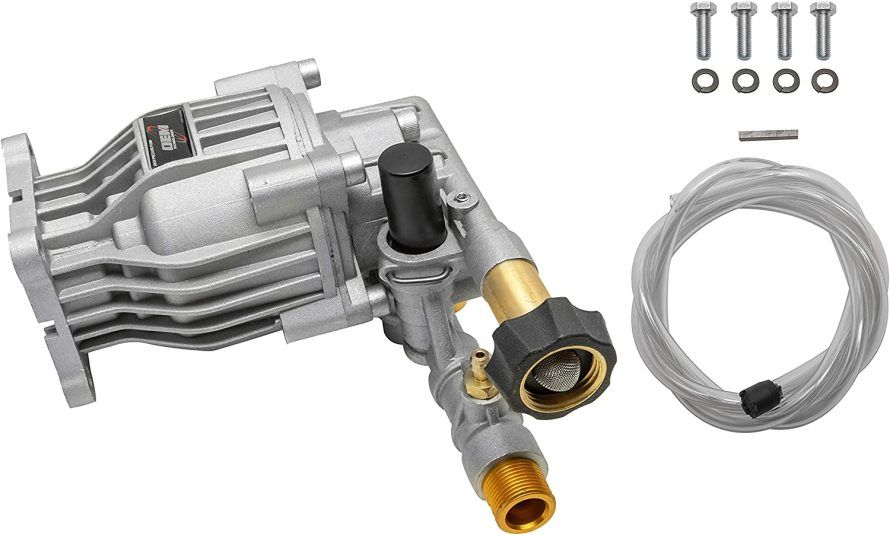

These are similar to triplex pumps but offer even more efficiency and durability than both of them combined. They’re also much quieter than any other type of pump out there right now, making them perfect for those who want their pressure washer to run quietly while still getting the job done well. So which one should you choose? It really depends on what’s most important to you, cost or performance? If you want something that performs well without breaking the bank then go with an axial cam pump, if you want something cheap then go with a wobble pump, if you want something that’s in between then go with a triplex pump.

These offer higher pressures at lower RPMs which means they’re great for energy efficiency as well as lower noise levels than other options out there on the market today but they do tend to be more expensive than other options available on the market today so keep that in mind before making your decision.

Working of Axial Cam Pumps

An axial cam pump is a piece of equipment that uses hydraulic pressure to move liquids or gases through pipes. It works by using two cylinders with grooves in them. One cylinder rotates, while the other stays still. As the moving cylinder goes around, it pushes against the stationary one, creating pressure along its length.

The benefit of an axial cam pump over other kinds of pumps is that it doesn’t require any electrical power, just water pressure from your plumbing system. This makes it great for remote locations where there’s no access to electricity. It’s compact and lightweight, so you can easily transport it wherever you need it to go.

Advantages of using Axial Cam Pumps

The advantages of using an Axial Cam Pressure Washer Pump are numerous. Here are just a few:

- They’re lightweight, which makes them easy to carry around.

- They have a high PSI output.

- They can handle both hot and cold water without any issues.

- They don’t require any maintenance or additional parts to work properly.

- They’re affordable compared to other pumps on the market today.

FAQ’s

Can you put any pump on a pressure washer?

Your pressure washer and your new pump must work together. Your pump cannot be changed for any other pump since they simply will not fit. Find out whether the pump in your pressure washer is an axial or triplex one.

Can I put a higher PSI pump on my pressure washer

Your pressure washer and your new pump must work together. Your pump cannot be changed for any other pump since they simply will not fit. Find out whether the pump in your pressure washer is an axial or triplex one.

How long does a pump last on a pressure washer?

A decent pressure washer pump should typically last 5 to 10 years when operated properly. Some inexpensive pumps might last considerably less time. Avoid overheating, cavitation, and running your pump with the incorrect unloader valve settings to get the most out of it.

What happens if pump pressure is too high?

High internal pressure in the pump puts strain on the impeller assembly, which in turn puts more pressure on the motor bearings. In the worst case scenario, the pump and motor will sustain damage. The pumped medium may potentially overheat and harm the pump if the flow rate is lower than the minimum flow rate necessary for the pump.

What causes a pressure washer pump to fail?

A defective unloader valve and a blocked carburetor are the two most frequent causes of the pressure washer pump failing (in the case of gas-powered washers).

How long do pressure pumps last?

A well pump typically has a lifetime of 8 to 15 years. Where your pump falls within that very large age range, though, depends on a variety of variables. The frequency of your pump’s duty cycle is the single biggest determinant of its lifespan.